Battery Electric Vehicles (BEVs) are rapidly transforming the automotive landscape, offering a compelling alternative to traditional gasoline-powered cars. This shift is driven by environmental concerns, technological advancements, and supportive government policies. From the intricacies of battery chemistry and motor technology to the challenges and opportunities presented by charging infrastructure and economic considerations, the world of BEVs is complex and constantly evolving. This exploration delves into the key aspects of BEV technology, infrastructure, economics, environmental impact, performance, and future prospects, providing a comprehensive understanding of this transformative sector.

Understanding BEVs requires a multifaceted approach, encompassing technological innovation, infrastructure development, economic feasibility, and environmental responsibility. This overview aims to provide a balanced perspective, exploring both the advantages and limitations of this burgeoning technology, while considering its impact on individuals, society, and the environment.

BEV Technology

Battery Electric Vehicles (BEVs) represent a significant advancement in automotive technology, offering a cleaner and potentially more efficient alternative to internal combustion engine vehicles. Understanding the underlying technology is crucial to appreciating their capabilities and limitations. This section will delve into the key technological components of BEVs, focusing on battery chemistries and motor technology.

Battery Chemistries in BEVs

Several battery chemistries are currently employed in BEVs, each with its own strengths and weaknesses. The choice of chemistry significantly impacts the vehicle’s performance, range, lifespan, and cost. The following table summarizes the characteristics of some common chemistries:

| Chemistry | Energy Density (Wh/kg) | Lifespan (cycles) | Cost ($/kWh) |

|---|---|---|---|

| Lithium Iron Phosphate (LFP) | 100-170 | 2000-3000 | 100-150 |

| Nickel Manganese Cobalt (NMC) | 150-250 | 1000-2000 | 150-250 |

| Nickel Cobalt Aluminum (NCA) | 200-250 | 800-1500 | 200-300 |

| Solid-State Batteries | >300 (Projected) | >5000 (Projected) | >300 (Projected) |

*Note: Energy density, lifespan, and cost figures are approximate and vary based on specific cell design and manufacturing processes. Solid-state battery figures represent projections based on current research.*

Evolution of BEV Motor Technology

BEVs utilize either AC (Alternating Current) or DC (Direct Current) motors. While both achieve the same outcome – converting electrical energy into mechanical energy to turn the wheels – they differ significantly in their design and characteristics. Early BEVs often employed DC motors, known for their simpler control systems. However, AC motors have become increasingly prevalent due to their higher efficiency, power density, and better controllability. AC motors, particularly permanent magnet synchronous motors (PMSM) and induction motors, offer superior torque characteristics across a wider speed range. Modern BEVs largely favor AC motors for their overall performance advantages.

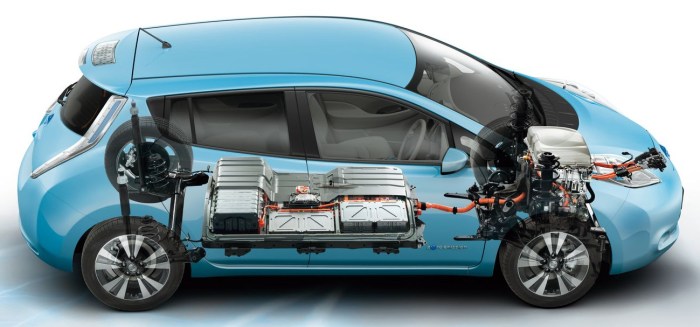

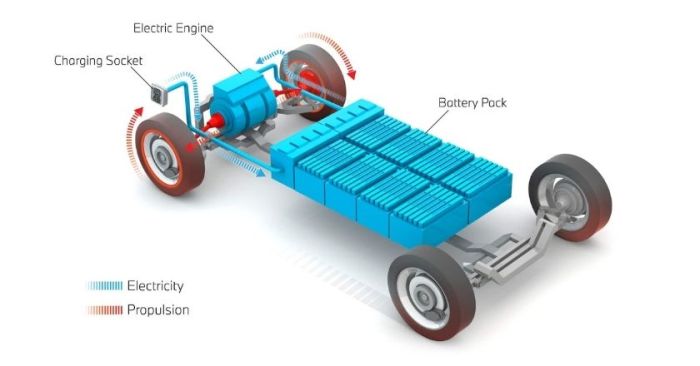

Energy Flow in a BEV

The following flowchart illustrates the path of energy from the battery to the wheels in a typical BEV:

“`

[Battery] –> [Power Inverter] –> [Electric Motor] –> [Transmission] –> [Wheels]

“`

The battery stores electrical energy. The power inverter converts the DC electricity from the battery into AC electricity suitable for the electric motor. The electric motor converts the electrical energy into mechanical rotational energy. The transmission (which may be a single-speed gearbox or even a direct drive system) transfers this rotational energy to the wheels, propelling the vehicle. Various control systems manage the energy flow and optimize performance based on driver input and vehicle conditions. Regenerative braking systems also feed energy back into the battery during deceleration, further improving efficiency.

BEV Infrastructure

The widespread adoption of Battery Electric Vehicles (BEVs) hinges critically on the availability and accessibility of a robust charging infrastructure. This infrastructure must not only meet current demands but also anticipate future growth in BEV ownership and usage, addressing geographical disparities and minimizing strain on the existing power grid. The following sections detail the various charging methods, the challenges and opportunities in infrastructure expansion, and the role of smart grid technologies.

BEV Charging Methods: A Comparison

Understanding the different levels of BEV charging is essential for both consumers and infrastructure planners. Each level offers a distinct balance between charging speed and power requirements, influencing both the user experience and the overall grid load.

- Level 1 Charging: This utilizes a standard 120-volt household outlet, offering the slowest charging speed. It typically adds around 3-5 miles of range per hour, making it suitable only for overnight charging or supplemental charging in situations where faster options are unavailable. Power requirements are minimal, drawing power directly from a standard home circuit.

- Level 2 Charging: Level 2 charging uses a dedicated 240-volt circuit, similar to that used for electric clothes dryers or ranges. This significantly speeds up charging, adding 10-80 miles of range per hour, depending on the vehicle and charger. Power requirements are higher than Level 1, often requiring dedicated circuits and potentially upgrades to home electrical systems. Public Level 2 chargers are commonly found in workplaces, apartment complexes, and shopping centers.

- DC Fast Charging: DC fast charging delivers high-voltage direct current directly to the vehicle’s battery, providing the fastest charging speeds. It can add hundreds of miles of range in a matter of minutes. However, this method demands significant power, requiring substantial infrastructure investment and potentially specialized grid connections. DC fast chargers are primarily located along major highways and in urban areas to support long-distance travel.

Challenges and Opportunities in BEV Charging Infrastructure Expansion

The expansion of BEV charging infrastructure faces several significant hurdles, particularly concerning geographic disparities. Rural areas, for example, often lack the population density to justify the significant upfront investment required for charging stations. This creates a “range anxiety” barrier for potential BEV adopters in these regions. Conversely, urban areas may experience challenges related to land availability, permitting processes, and grid capacity limitations.

Opportunities exist in leveraging innovative solutions such as wireless charging, vehicle-to-grid (V2G) technology, and strategic partnerships between private companies and government agencies. Government incentives, grants, and regulations can play a vital role in stimulating investment and ensuring equitable access to charging infrastructure across all geographical areas. For instance, the US government’s investment in the Bipartisan Infrastructure Law includes significant funding for EV charging infrastructure development, aiming to address these geographic disparities.

The Role of Smart Grid Technologies in Optimizing BEV Charging

Smart grid technologies offer a crucial solution to the challenges of integrating a large number of BEVs into the existing power grid. Smart charging systems can optimize charging schedules based on electricity prices, grid load, and renewable energy availability. This can significantly reduce peak demand, minimize strain on the grid, and potentially lower overall energy costs for both consumers and utilities. Examples include algorithms that dynamically adjust charging rates based on real-time grid conditions, or systems that prioritize charging during periods of low demand or high renewable energy generation. Furthermore, V2G technology allows BEVs to feed excess energy back into the grid during peak demand, further enhancing grid stability and resilience.

BEV Economics and Policy

The economic viability and widespread adoption of Battery Electric Vehicles (BEVs) are significantly influenced by a complex interplay of factors, including initial purchase price, running costs, and government incentives. Understanding these elements is crucial for both consumers considering a BEV and policymakers aiming to accelerate the transition to sustainable transportation.

Total Cost of Ownership Comparison: BEV vs. ICE

The total cost of ownership (TCO) for a vehicle encompasses all expenses over its lifespan. While BEVs typically have a higher upfront purchase price, their lower running costs can offset this over time, leading to potential long-term savings. However, the exact TCO comparison varies depending on factors such as electricity prices, driving habits, and vehicle model. The following table provides a simplified comparison, using average figures and assuming a 5-year ownership period. Note that these are estimates and actual costs may vary considerably.

| Vehicle Type | Purchase Price | Maintenance Costs | Fuel Costs (over 5 years) |

|---|---|---|---|

| BEV (Small Hatchback) | $30,000 | $1,500 | $1,500 (assuming average electricity cost and mileage) |

| ICE (Small Hatchback) | $25,000 | $3,000 | $6,000 (assuming average gasoline cost and mileage) |

Government Policies and Incentives for BEV Adoption

Governments worldwide are implementing various policies and incentives to encourage BEV adoption. These initiatives aim to overcome the higher initial cost barrier and stimulate demand. Common incentives include tax credits or rebates on the purchase price, exemptions from road taxes or tolls, access to dedicated high-occupancy vehicle (HOV) lanes, and subsidized charging infrastructure. For example, the US federal government offers a tax credit for the purchase of new electric vehicles, while many European countries provide substantial subsidies and tax breaks. These policies are often coupled with stricter emission regulations for internal combustion engine (ICE) vehicles, making BEVs a more attractive option.

Impact of Battery Material Prices on BEV Cost

The cost of battery materials, including lithium, cobalt, nickel, and graphite, significantly impacts the overall price of BEVs. Fluctuations in the prices of these raw materials directly affect the manufacturing cost of batteries, which constitutes a substantial portion of a BEV’s total cost. For instance, a surge in lithium prices can lead to an increase in the price of BEVs, potentially hindering their adoption. Research and development efforts are focused on securing alternative battery chemistries that rely less on these expensive and geographically concentrated materials, thereby potentially reducing the cost and environmental impact of BEV batteries. Furthermore, advancements in battery manufacturing technologies and economies of scale are also expected to contribute to a decrease in battery costs over time.

BEV Environmental Impact: Battery Electric Vehicles (BEVs)

The environmental impact of Battery Electric Vehicles (BEVs) is a complex issue, encompassing the entire lifecycle of the vehicle, from raw material extraction to end-of-life disposal. While BEVs offer significant advantages in reducing tailpipe emissions compared to Internal Combustion Engine (ICE) vehicles, a comprehensive assessment requires considering the environmental footprint across all stages. This analysis compares the greenhouse gas emissions and pollution impacts of BEVs and ICE vehicles, examines the environmental consequences of battery production and recycling, and highlights the potential of BEVs to improve air quality in urban environments.

The lifecycle greenhouse gas emissions of BEVs are often lower than those of ICE vehicles, but the difference varies significantly depending on several factors, including electricity generation mix, vehicle size and battery chemistry, and driving patterns. Manufacturing BEVs requires significant energy, leading to emissions associated with the production of battery components, vehicle assembly, and transportation. However, operational emissions are substantially lower for BEVs, as they produce zero tailpipe emissions. End-of-life impacts depend heavily on the effectiveness of battery recycling programs. A well-functioning recycling system can significantly reduce the environmental burden associated with battery disposal. Conversely, inefficient recycling can lead to increased emissions and environmental damage. A comprehensive life cycle assessment (LCA) is crucial to accurately compare the overall environmental performance of BEVs and ICE vehicles. For example, studies have shown that even in regions with a high reliance on fossil fuels for electricity generation, BEVs can still have a lower carbon footprint over their lifespan than comparable ICE vehicles, particularly over longer driving distances.

Lifecycle Greenhouse Gas Emission Comparison

Studies consistently show that the total lifecycle greenhouse gas emissions of BEVs are generally lower than those of equivalent ICE vehicles, even when considering the carbon footprint of electricity generation. This advantage is more pronounced in regions with a higher proportion of renewable energy sources in their electricity grid. However, the magnitude of the difference is highly variable, dependent on factors such as the type of battery used, the energy efficiency of the vehicle, and the driving habits of the owner. For instance, a BEV charged primarily with electricity from coal-fired power plants will have a higher carbon footprint than one charged with renewable energy. Similarly, a larger, heavier BEV will have a higher manufacturing carbon footprint than a smaller, lighter model. These complexities highlight the importance of considering the entire lifecycle and regional variations when comparing the environmental impact of BEVs and ICE vehicles.

Environmental Impact of Battery Mining and Recycling

The mining of raw materials for batteries, particularly lithium, cobalt, and nickel, can have significant environmental consequences.

- Habitat destruction: Mining operations can lead to deforestation and habitat loss, impacting biodiversity.

- Water pollution: Mining activities can contaminate water sources with heavy metals and other pollutants.

- Air pollution: Mining and processing of battery materials can release harmful air pollutants.

- Social impacts: Mining operations can have negative social impacts on local communities, including displacement and human rights violations.

Effective battery recycling is crucial to mitigating these environmental impacts. A robust recycling infrastructure can recover valuable materials, reduce the demand for new mining, and minimize waste disposal. However, current battery recycling technologies are still under development, and improvements in efficiency and cost-effectiveness are needed to make recycling widely adopted. Advancements in battery chemistry are also crucial, with research focusing on developing batteries with more easily recyclable materials and designs. For example, the development of solid-state batteries holds promise for improved recyclability and reduced environmental impact.

Potential for BEV Air Pollution Reduction in Urban Areas

BEVs contribute to reduced air pollution in urban areas by eliminating tailpipe emissions of pollutants such as particulate matter, nitrogen oxides, and carbon monoxide. These pollutants are major contributors to respiratory illnesses and other health problems. The shift towards BEVs can significantly improve air quality, particularly in densely populated urban centers with high traffic volumes. This improvement in air quality translates to significant public health benefits, reducing healthcare costs and improving overall well-being. Cities with high adoption rates of BEVs are already seeing noticeable improvements in air quality indicators, demonstrating the tangible benefits of transitioning to electric transportation. For instance, several European cities have reported significant reductions in air pollution levels following increases in BEV adoption.

BEV Performance and Features

Battery Electric Vehicles (BEVs) are rapidly evolving, offering compelling performance and a suite of innovative features that are reshaping the automotive landscape. This section will delve into the key performance characteristics of BEVs, comparing them to their Internal Combustion Engine (ICE) counterparts, and exploring the advanced safety and unique features that define the BEV driving experience.

Performance Characteristics Compared to ICE Vehicles

Understanding the performance differences between BEVs and ICE vehicles is crucial for prospective buyers. While generalizations can be made, specific performance varies greatly depending on the model and manufacturer.

- Acceleration: BEVs generally offer superior acceleration due to the instant torque delivery of electric motors. This results in quicker 0-60 mph times compared to most ICE vehicles, especially those with smaller engines. For example, many Tesla models boast significantly faster acceleration than comparable gasoline-powered sedans.

- Range: Range is a critical factor for BEV adoption and is heavily influenced by battery size, driving style, weather conditions, and terrain. While BEV range is constantly improving, it typically lags behind the driving range achievable with a full tank of gasoline in many ICE vehicles. However, advancements in battery technology are rapidly closing this gap.

- Handling: The lower center of gravity in many BEVs, due to the placement of the battery pack, often contributes to improved handling and stability, particularly in corners. This can lead to a more responsive and engaging driving experience compared to some ICE vehicles, although this can vary based on the specific vehicle design.

Safety Features in BEVs

Safety is paramount in modern vehicles, and BEVs often incorporate advanced safety features that go beyond those found in many ICE vehicles. These features contribute to accident prevention and mitigation.

- Advanced Driver-Assistance Systems (ADAS): Many BEVs come standard or as optional upgrades with ADAS features such as adaptive cruise control, lane keeping assist, automatic emergency braking, and blind-spot monitoring. These systems utilize sensors and cameras to enhance driver awareness and prevent accidents.

- Stronger Body Structures: The design of BEVs often incorporates stronger body structures to protect occupants in the event of a collision. The battery pack’s placement can also contribute to improved structural rigidity.

- Over-the-Air Updates: BEVs often receive over-the-air software updates that can improve safety features and performance over the vehicle’s lifespan. This allows manufacturers to address vulnerabilities and introduce new safety enhancements without requiring a physical visit to a service center.

Innovative Features Unique to BEVs

Beyond performance and safety, BEVs boast several innovative features that are unique to electric powertrains.

- Regenerative Braking: Regenerative braking captures kinetic energy during deceleration and converts it back into electricity, recharging the battery. This extends the vehicle’s range and reduces wear on the friction brakes.

- One-Pedal Driving: Some BEVs offer one-pedal driving, allowing drivers to accelerate and decelerate using only the accelerator pedal. The regenerative braking system is highly effective, enabling smooth deceleration and potentially eliminating the need for the brake pedal in many driving situations.

- Silent Operation: The near-silent operation of BEVs is a unique characteristic, leading to a quieter and more refined driving experience, particularly in urban environments.

Future of BEVs

The future of Battery Electric Vehicles (BEVs) is bright, driven by continuous technological advancements and supportive government policies. While challenges remain, the trajectory points towards a significant increase in BEV adoption and a transformation of the automotive landscape. This section explores key emerging technologies and their impact on the widespread acceptance of BEVs.

The next decade will witness a dramatic shift in BEV technology, significantly impacting range, charging times, and overall performance. These advancements are not merely incremental improvements but represent paradigm shifts that could accelerate the transition to electric mobility.

Emerging BEV Technologies

Several emerging technologies are poised to revolutionize the BEV market. Solid-state batteries, for example, offer significantly improved energy density compared to current lithium-ion batteries, promising longer ranges and faster charging times. Unlike lithium-ion batteries which use a liquid or gel-like electrolyte, solid-state batteries employ a solid electrolyte, leading to enhanced safety and stability. Companies like Solid Power and QuantumScape are actively developing and testing these next-generation batteries, with projections indicating their commercial viability within the next few years. Wireless charging, another promising technology, eliminates the need for physical connections, simplifying the charging process and potentially integrating charging infrastructure into roadways and parking spaces. While still in its early stages of development, wireless charging technology is showing considerable promise for convenience and scalability.

Impact of Battery Technology Advancements

Advancements in battery technology will directly influence two critical aspects of BEV adoption: range and charging times. Increased energy density translates to longer driving ranges on a single charge, addressing one of the major concerns associated with BEVs – range anxiety. For example, current BEVs typically offer a range of 200-300 miles, but solid-state batteries could potentially double or even triple this range. Similarly, faster charging speeds, enabled by improved battery chemistry and charging infrastructure, will reduce the time required to replenish the battery, making BEVs more convenient for daily use. For instance, current fast-charging technologies can add 80% charge in about 30 minutes; future technologies could reduce this time significantly.

Projected Growth of BEV Sales, Battery Electric Vehicles (BEVs)

Predicting the future is inherently challenging, but based on current trends and technological advancements, a significant growth in BEV sales is anticipated over the next decade. Several factors contribute to this projection, including increasingly stringent emission regulations, government incentives, falling battery costs, and growing consumer awareness of environmental concerns. While precise figures vary depending on the source and underlying assumptions, a conservative estimate suggests a fivefold or greater increase in global BEV sales by 2033, compared to 2023 levels. This growth will be unevenly distributed geographically, with regions having strong government support and robust charging infrastructure experiencing faster adoption rates. For instance, the European Union’s ambitious targets for emissions reduction are expected to drive substantial growth in BEV sales within the region. Similarly, China, with its significant investment in BEV manufacturing and infrastructure, is projected to be a major market driver. This growth, however, is not without its challenges, including the need for substantial investment in charging infrastructure and the availability of critical raw materials required for battery production.

The transition to Battery Electric Vehicles (BEVs) presents a significant opportunity to reshape the automotive industry and address pressing environmental challenges. While hurdles remain, particularly concerning infrastructure development and battery technology limitations, ongoing innovation and supportive policies are paving the way for widespread BEV adoption. The future of transportation is undeniably electric, and understanding the complexities and potential of BEVs is crucial for navigating this exciting and transformative period. The continued advancements in battery technology, charging infrastructure, and supportive government initiatives promise a future where BEVs are not only a viable option but the preferred mode of transportation.

Common Queries

What is the range of a typical BEV?

The range of a BEV varies significantly depending on factors such as battery size, driving style, weather conditions, and vehicle features. Ranges typically range from 100 to over 300 miles on a single charge.

How long does it take to charge a BEV?

Charging times depend on the charging method and the BEV’s onboard charger. Level 1 charging is slow, taking many hours. Level 2 charging is faster, typically taking several hours. DC fast charging can provide a significant charge in under an hour.

Are BEV batteries recyclable?

Yes, BEV batteries contain valuable materials that can be recycled. Recycling processes are becoming increasingly sophisticated, aiming to recover and reuse these materials to minimize environmental impact and reduce reliance on new mining.

How do BEV’s compare to ICE vehicles in terms of maintenance?

BEVs generally require less maintenance than ICE vehicles, as they have fewer moving parts. However, battery replacement can be a significant cost later in the vehicle’s life.

What are the safety features of BEVs?

BEVs often include advanced safety features such as automatic emergency braking, lane departure warning, adaptive cruise control, and numerous airbags, comparable to or exceeding those found in ICE vehicles.